Home | Products | CNC Threading System | ML SERIES MACHINING SYSTEM

ML SERIES MACHINING SYSTEM

In-situ & Tubular Threading Technologies in association with the Eurotechnology Group announces the introduction of the new ML Series CNC Threading Systems complete with integrated tool changer, high accuracy pipe alignment lasers integrated with the Pendleslide® pipe alignment system, programmable Vee type Servo controlled rear pipe steady clamps for securing pipe & pup joints while machining.

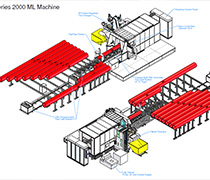

- 20” Series 2000 Machine System.

- Fanuc Screen display function with remote access for on-line diagnostic and operational support from In-Situ(if required).

- 1 off HMOP Fanuc handy panel.

- Custom designed Fanuc Picture screen for Operator assistance and Diagnostic (see Fig2)

- CE marked Rittal enclosure housing all control gear and associated equipment.

- In-Situ Rotating head with CNC controlled X Axis movement to allow turning operations on stationary pipe.

- Fanuc Alpha iI40/6000HV AC Spindle motor.

- Z Axis linear movement by four precision preloaded linear bearings.

- Dual preloaded precision ballscrews on Z Axis.

- Hydraulic power pack to suit.

- Fully integrated high pressure (up to 70Bar) coolant system with paper band filter.

- Through spindle coolant.

- Swarf conveyor.

- Completely enclosed machine guarding, operator sliding access door with safety interlock system.

- 1 set of Fanuc Manuals, Installation layout, Maintenance, Parts and operation manuals.

- 1 Set of Foundation Drawings and elevation details.

- Necessary outputs (Machine in cycle, Pipe Clamped/Unclamped, Emergency stop) to interface with handling equipment.

SPECIFICATION - BASE MACHINE

- 1 OFF fully integrated automatic tool changer complete with tool chain magazine with (no. of tool stations TBA), complete with 180° rotary gripper designed for Capto C6 toolchanging.

- 1 OFF Sandvik Capto toolholder with integrated auto tool change capability.

- X axis Direct feedback via Renishaw Resolute® scale (Closed Loop).

- Moog® Rotary data communication for X Axis scale.

- Z axis Direct feedback via Heidenhain scale (Closed Loop).

- 1 OFF Renishaw RMP60 probe integrated to enable finished in-machine probing with wireless data transmission.

- 1 OFF Renishaw CNC reporter probe evaluation software (PC free issue)

- Programmable In-Situ Servo controlled 4 Jaw Chuck 22” through bore. Operating range 22"- 2 7/8" without Jaw change.

- Programmable 4 off High accuracy pipe alignment lasers integrated with the Pendleslide® pipe alignment system. Programmable Vee type Servo controlled rear pipe steady clamps for securing pipe & pup joints while machining.

- 1 off Servo controlled, Height programmable, pipe handling system to lift, feed in/out & lower onto customer pipe rack, c/w facility to handle pup joints minimum length 36".Range 2 7/8" - 20" OD. Complete with hydraulic motors for Z plane movement of steady's.

SPECIFICATION – ADDITIONAL EQUIPMENT

Technical Data - General

| CNC Control | Fanuc 32i-TB* |

| Machining Capacity | 2 3/8” to 20” Diameter |

| Spindle Speed | Infinitely Variable 0-600 Rpm |

| Maximum Spindle Motor Speed | 6000 Rpm Limited to 4200Rpm |

| Spindle Motor to Spindle Ratio | 7:1 |

| Spindle Motor Power | 40Kw |

| X Axis Rapid Traverse Rate | Up to 15000 mm/min |

| X Axis Travel | 160 mm Radial |

| X Axis Feedback | Renishaw RSLA Absolute Linear Encoder |

| Z Axis Rapid Traverse Rate | Up to 15000 mm/min |

| Z Axis Travel | 600 mm* |

| Z Axis Feedback | Heidenhain LC493F Absolute Scale |

| AL1 (Laser slide 1) | 750mm* |

| AL2 (Laser Slide 2) | 750mm* |

| AL3 (Laser Slide 3) | 750mm* |

| AL4 (Laser Slide 4) | 750mm* |

| JAW AJ1 (6 O’Clock) Stroke | 282mm* |

| JAW AJ2 (12 O’Clock) Stroke | 282mm* |

| JAW AJ3 (3 O’Clock) Stroke | 282mm* |

| JAW AJ4 (9 O’Clock) Stroke | 282mm* |

| Machine Foot Print (Excluding Associated Equipment) |

Length 6.06M* Height 2.6M* Width 2.44M* |

| Machine Centreline | 1177mm* |

| Machine Weight | 36,000Kg |

| Way lube oil type | AWS 46 |

| Hydraulic Power Pack oil type | HWS 32 |

| Machining Head – Gears oil type | R2 |

| Machining Head – Slide oil type | TX220 |

| Coolant Capacity | 200 Litres |